A comfortable cusocks comes from premium raw material and a beautiful sock comes from well-designed patterns. A good custom sock design have to be visually fantastic, which is what most UI designers do, but a good sock designer needs also to know about sock knitting process, on top of that to understand how the yarn color look different compared to their look on screens.

Knitting of Custom Socks

Just like regular socks, custom knitted socks are knitted loop by loop from top to end. In each loop, there will be different numbers of stitches depending on the knitting needle count. The typical needle counts are 96, 128, 144, 168, 200N. Below is the inside view of a old-fashioned hand-operated sock knitting machine, which uses a roughly 60N stitches, as you can see the knitting is coarse and the yarn is thick.

In SockCustomTM we only make socks with 200N knitting, which is the finest knitting technology on the market. This means we have to feed in more yarn to knit a sock, but in return we get a better-feeling sock and a sharper resolution of knitted logos or patterns.

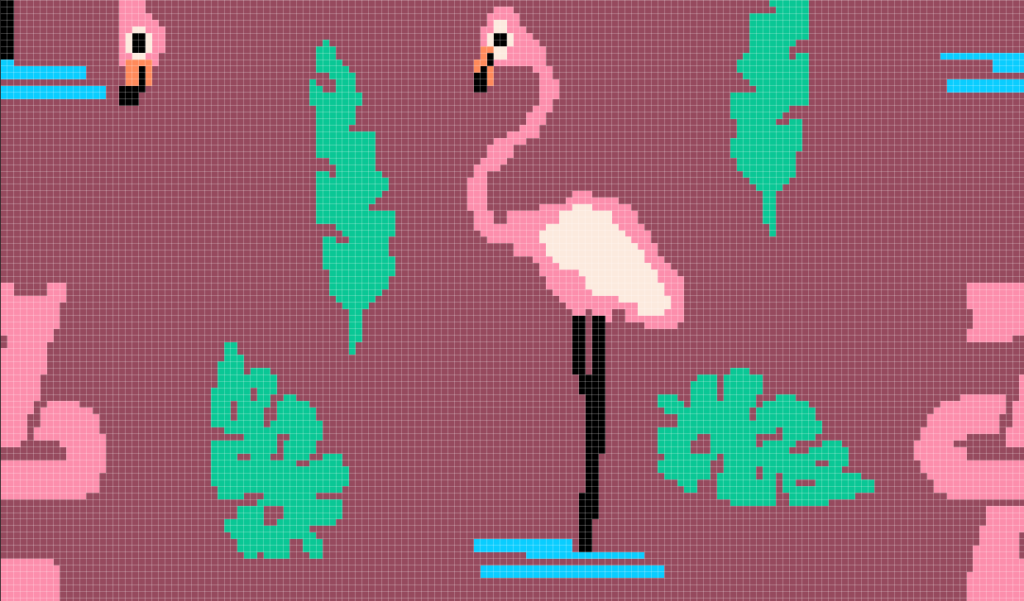

The knitting of 200N stitches also means that in one loop, the resolution is 200 pixels in width, which needs to be aligned with our sock designs. You can see this clearly in the following sock design where the resolution is 200 pixels in width.

Also note that the sock design itself is a rectangular, this is like when you cut off a sock from top to toe and the sock tube becomes a rectangular cloth. You can also see n the sock design that the left and right sides meet each other so that we make sure no patterns will break on the sock tube.

We all know that a 1080P-23.8 inch screen is 1920 x 1080 pixels, with the high resolution you are able to see any graphics without seeing each pixels. This is however not the case with custom made logo socks. Since the resolution is only 200 pixels, your logo will be knitted out not as fine as what you see on screen. You can also see this effect in the right-hand image above.

The Real Yarn Colors in Industry

With a nice design it’s essential to find the right matched yarn so that the sock comes out as expected. To match colors designers prefer to use pantone match system or normal UI color systems like CMYK or RGB, but in the sock industry, we use the a system called SanShan color-matching-system.

Of course you don’t have to know much about the color matching system, our designers will take care all of it!

Kindly note that even with the same yarn color, the yarn might look slightly different for different batches of production, the colors are dyed in raw yarn and their colors are affected by operating time, humidity, temperature, pressure etc.

Best Practice in Custom Sock Designs

With all our experience in the knitting process and color-matching projects, we have some best practices that we implement in our daily custom sock projects. These best practices is also the take-away if you want to design your own socks.

See through in custom socks (avoid dark base colors)

A see through problem in socks is that when the sock’s base color is dark and the logo color is light, the base color will easily be seen through. In the custom sock sample below you can see that the base color is black and the logo color is light pink. This leads to the problem that you can easily see black colors through the pink logo, which is definitely not what the sock designer expect.

So in this project, try a bright base color will work fine.

Total number of colors used in a custom socks

As we have discussed that the socks are knitted out loop by loop, but where does the colorful patterns come from, well, they are knitted as an extra layer on top of the base colors. This is also the reason why you can easily see dark base colors through light logo areas.

When you setup the machine with corresponding colors in different channels, the machine start knitting the sock intelligently. Each time the machine detects a logo color needs to be knitted, it feeds in the corresponding yarn and then cut it where the color stops, due to this process there is a limited number of colors allowed in each loop.

In SockCustomTM we can take care of a maximum of 5-6 colors in one sock, and our designer will take this into account if your logo contains too many colors.

Custom sock cuff, toe, and heel: Use solid colors

In most designs we use solid colors on these three specific areas: cuff, heels and toe and we usually use only one color in contrast with the sock background color. The contrast makes the sock more brilliant otherwise the design will look boring.

The cuff area is usually knitted with loose stitches so basically there are less resolution (remember we talked about this in the first section?) in this area, meaning if we knit patterns it will look coarser. In the example sock below you can easily see that the knitting in the cuff is woarse than the sock tube.

Gradient colors into several solid colors

What if there are gradient colors in your logo or pattern? In this case usually customers needs a custom printed solution, however why don’t we convert the gradient colors into solid colors, for simplicity and much better sock quality (against printed socks, you can find more about custom printed socks via this link)?

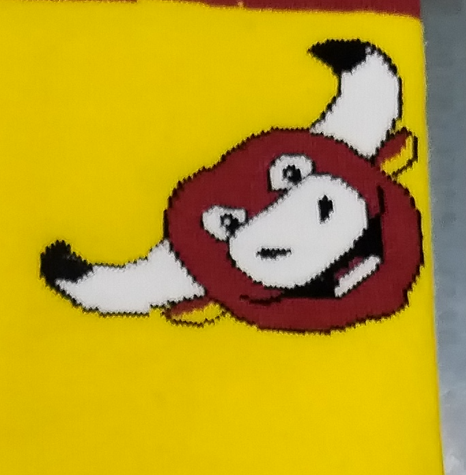

In the following custom sock project we managed to replace the gradient colors with several solid colors and the patterns turns out to be great!

Repeating patterns

A simple logo might feel lonely in the whole sock, why not repeating the logos around the sock? This aligned logos create a feel of consistency thus being good for brand awareness.

Match the right yarn colors

When you have a sock design and you want to choose the right yarn color to knit socks, it’s more important to match an appropriate colors, than to match the closest color. This is because a color series might look fantastic on screen but turns out less promising.

Avoid using thin lines

It is always recommended to use block color rather than thin lines on a sock design. As we mentioned above the patterns will be knitted pixel by pixel so a thin line will be constructed by a series (chain) of pixels.

If the thin line is vertical or horizontal it won’t be a big problem for sock knitting, however if the line is curved or declined, you will then see a pixelated line which is not as expected.

Moreover, each pixel will be represented by a stitch of sock yarn which will look like the symbol “^” on socks. In the following example you can see the designed logo pixels and the corresponding knitted effect of the logo.

Conclusion

In this post we discussed about the knitting process of custom socks and how sock yarn color matching works in the industry. And we shared some best practices (as takeaways) that our experienced designers are implementing everyday.

That is a very good tip particularly to those fresh to the blogosphere.

Simple but very precise info… Appreciate your sharing this one.

A must read article!